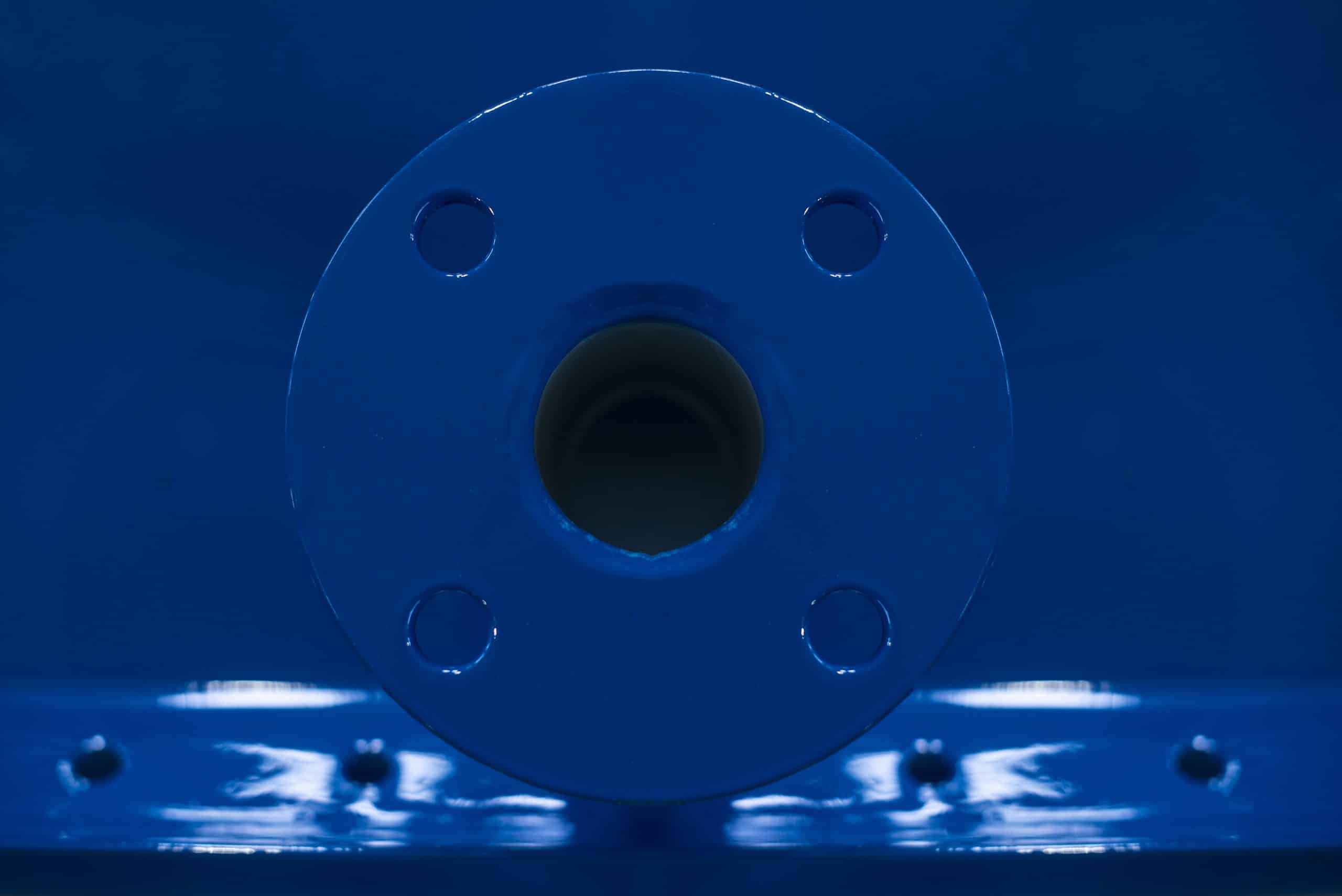

Fully automated in-house powder coating line

ABECO pioneered galvanised steel water storage solutions in 1983 and over the LAST 40 years continued to lead the industry by consistently staying ahead of the curve. ABECO quickly became the market leader with its high-quality galvanised steel rectangular and circular tanks.

Always focusing on being ahead of the curve, ABECO identified a need in the market for an additional solution that would be more aesthetically pleasing, and epoxy-based powder coating was the answer. They invested time, research and development, and capital into finding a solution that would complement its existing offering and continue its market growth strategy.

“We are constantly looking for new ways to innovate in the industry and follow global trends.”